After nearly 20 years

of APO DP organization have alternative from SAP; SAP IBP for Demand

Many organizations

have already implemented APO DP or third party Demand Planning tools. Many opted for third party Demand Planning so

called best of breed tools.

Overview APO Demand Planning

DP form part of the

APO SCM suite that was launched nearly 20 years ago.

Simply stated setting

up APO DP requires substantial effort not only to define characteristics that

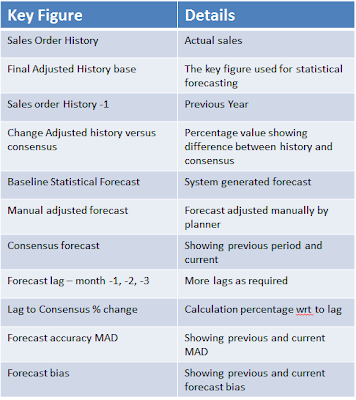

are planned but the all the relevant key figure , info objects, planning area planning books and data views. This

effort also due to technological constraints; available technology 20 years ago. To support

all this set-up complex macros are required for data calculation and how data

is viewed. Basic data views such as waterfall report require major set-up and

job sequencing.

Once this was done and

handed over usability became a problem whereby planners still used the good old excel to massage data

or totally ignored the DP solution basically copied data from excel into one of

the data views.

One major advantage

offered by APO DP relates to release of forecast to the SNP (Supply network

planning) and PPDS (Production Planning

and Detailed Scheduling) without the need of interfaces which are needed for

third party demand planning tools.

Planner using DP are heavily

dependent on back -office for any variation or flexibility wrt to data views,

data processing.

Data integration

required complex ‘BW’ type update from ERP system to the APO system in order to

get source data.

With all its positive and

negative factors organizations were able to generate decent forecast accuracy.

APO Moving On

SAP has now released an OSS note 2456834 – Transition Guide for SAP APO stating that “SAP APO is partially succeeded by two products: SAP S/4 HANA and SAP Integrated Business Planning (SAP IBP)”. SAP APO will be under general support till 2025 (extended from 2020 earlier) part of SAP Business Suite. Currently SCM 7 EhP 3 is most recent Enhancement Package for APO, there is no guidance for EhP 4 or any future enhancement packs for SCM or APO.APO has mainly 4 sub-modules – DP. SNP. GATP and PPDS. Below figure shows the high-level functionalities of each sub-module and SAP’s roadmap for these functionalities to the successor products. DP and SNP will be succeeded by IBP, GATP & PPDS will be succeeded by similar functionalities in S/4HANA.

IBP is a cloud application and AATP is a new name for functionalities of GATP in S/4HANA. Architecture, configurations, user interface for IBP and AATP are very different w.r.t APO .Hence, transition to successor products should be through new configurations i.e existing APO configurations can not be reused for IBP and AATP in S/4HANA. SAP has also clearly stated in the note that “An automated migration from SAP APO to the successor products is not possible“.

It is also now apparent that the future SAP landscape for customers using APO DP and SNP will need to be Hybrid i.e a mix of On-premise (Core ERP or S/4HANA) and Cloud (IBP).

IBP has been launched few years and many customers have started using it or migrated to it. PPDS has been merged in 1610 release of S/4HANA.Some parts of APO GATP have been made available in 1610 release of S/4HANA and SAP has also provided a road map for AATP as depicted in below figure.

Rule-based ATP (RBA) with substitution functionality of GATP is used by several customers, however, that is not yet available in AATP of S/4HANA. The first version of RBA is expected in 1808 release of S/4HANA.

As of now, APO functionalities are partially available in its successor products S/4HANA and IBP. We need to wait and watch when APO can be fully migrated to S/4HANA and IBP. However, it is very clear now that SAP is recommending to plan for transition from APO to its successor products IBP and S/4HANA.

What is not clear is

the migration path with respect to industry solutions such as automotive, mill,

cable. The assumption is that they will be migrated to relevant space. Cable

solution which utilizes combination of ATP and PPDS will move to SAP S/4HANNA

ATP and PPDS space.

IBP Demand Planning

Firstly IBP demand

planning is about excel therefore good-bye SAP GUI.

The demand planning

tool exploits excel via SAP provided add-on for excel providing user maximum

flexibility to adapt data to different planning conditions.

This implies usability

is based on excel plus additional features that are possible such as setting

graphs and the way data is presented . Furthermore

it does not need complex macro as per APO DP to manage cell; changes , color, text size. Via excel EPM formatting cells can be formatted to

choose desired purpose so that changes are highlighted differ colors, borders, text

size.

Within the same view alerts

are automatically shown in different colours controlled by user and not back

office.

Apart from excel user

will access SAP Fiori;

HTML5 based access via

web browser and is technological adaptive to different dives, laptop, tablet , smart

phone . Via controlled authorization user will access IBP SAP Fiori for loading

data, deciding on forecasting techniques (algorithms) , set up promotional

planning data and viewing analytics.

Furthermore via SAP

JAM used for collaboration, IBP for

demand will be totally integrated so that different teams can progress in efficient

manner the demand management process; historical data review and cleansing, forecasting

review, consensus, market review. The

total integration allows for predefined planning view structured for relevant

teams without wasting time in creating data view. Example ; for consensus planning

there will be a planning view structured

specifically product family, market and in desired time buckets.

Apart from usability,

flexibility in viewing data in within different versions, planning in different

versions user totally independent from back office and system is highly

adaptive to user needs.

ID Demand also has

major improvement offering new forecasting algorithms, furthermore forecasting model can have

multiple algorithms associated so that best fit solution can be determined with

a view in maximizing forecast accuracy.

ID demand also offers

scenario planning; planner can on the fly create a scenario for review with

other teams which is then tailored/ modified and then accepted within baseline

version. This implies not only having

multiple scenario; baseline, upside, downside but ability to create on the fly scenario

(what if promotion lift due to marketing campaign) which are then reviewed with

the collaboration tool.

Possible APO to IBP migration

So invested million in

APO third party; what next ?

Incentive to migrate

to IBP is the following:

- Current APO DP solution not providing real business benefits, poor forecast accuracy due to its design, usability, rigidity and lack of forecasting algorithms.

- End of APO support 2025. C

- Consolidate third party tool to IBP Demand Planning with a view exploiting IBP Demand , S&OP and Control Tower