In order to effectively design and implement APO Demand Planning any organization, it is important have a clear working framework. Critical aspect to consider is that Demand Management is an approximation; it is never a pure science. There is quite a difference between forecasting and Demand Planning, forecasting is a mathematical action while Demand Planning is a process where forecasting if part of the process.

The objective of this post is provide food for thought regarding the Demand Management process.

The key objective is to achieve an efficient Demand Management system that is user friendly ( different user profiles), has the required technical enablers (forecast procedure) and is able to achieve primary objective of maximizing throughput of the organization taking into consideration business complexities:

• Supply chain pattern; make to order, make to stock, export markets, VMI, toll manufacturing, late pack customization ect..

• Product life cycle

• Proliferation of products

• Different roles in the business impacting Demand Planning

SAP APO Demand Planning is one of the most un-structured solution in SAP; un-structured implies that the whole Demand Planning solution has to be built with the provided technical framework. It is purposely un-structured in that it has to be built to satisfy business requirements with respect to data views, data aggregation and data manipulation.

In order to effectively manage Demand Planning it is critical to understand the following:

• The technical framework provided by SAP DP

• Key elements in the technical framework provided by SAP DP

• The Demand Planning Process

DP TECHNICAL FRAMEWORK

This framework is provided SAP in the APO Demand Planning system

SAP Technical Framework

This framework is provided by SAP to build the DP solution and consists of:

- Planning Area where data is stored and manipulated

- Planning book’s and data view; the user front end for managing Demand Planning. Characteristics and key figures. This is the most critical area for user management.

- Info Cube in the Data warehousing system needed for feeding data to the Demand Planning solution

The above must be specifically set-up to satisfy the business requirements and is supported by elements described below.

ELEMENTS IN THE FRAMEWORK

Within the framework there are additional elements provided by SAP DP framework, these are:

- Macro’s for manipulating data and presenting data in user friendly-way (example red cell for exception )

- Data aggregation management; critical for data viewing and data consistency

- Standard forecasting models

- Standard forecast error calculation formula

- Tool-set for phase-in, phase-out, interchangeability

- Characteristics based planning

- Ability to upload data back to Data warehousing info cube

- Ability to integrate Demand Planning data with other Supply Chain tools such as Supply network planning, production , Sales and Operations Planning

- Authorization control

- Exception and alert management

The above all play a critical role in setting up an effective Demand Management solution and need to be carefully addressed.

THE DEMAND PLANNING PROCESS

The Demand Planning in most cases consists of a number of steps, different resources, different data granularity for each process, business and supply chain constraints. Therefore critical to understand the process so that correct and effective Demand Planning framework can be set-up. In certain cases too much time is wasted in addressing a forecasting formula or forecast accuracy formula instead of understanding clearly the DP process. The understating of the process and exploiting the technical framework will ensure the correct level of user-friendliness and desired objective.

Demand Planning Process

The Demand Planning process consists of:

- History Management or data preparation for actual forecasting process; preparing base data for forecasting

- The actual forecasting and forecasting review process

- Consensus Management with different role players; marketing and sales , manufacturing to determine agreed final forecast with different business process owners.

- Alert and exception management applicable to all three of the above processes to ensure more efficient data management. Critical for forecast accuracy, data manipulation (copying from one cell to another, mathematical calculation) and data presentation (red cell for phase-out period)

Furthermore the process is controlled / constrained by organization procedure (monthly forecasting) , market behaviors and supply chain patterns.

The process is also managed by different resource that require unique data granularity; consensus forecasting with sales and marketing require data to be aggregated by brand, my markets, channel ect..

Understanding the above then determine how to exploit the provided framework.

HISTORY MANAGEMENT PROCESS

The purpose of history management is to provide clean base history data that will be the input to generating the statistical forecast. This is extremely critical, forecast calculation and accuracy becomes irrelevant if you based data is not meaningful.

This data view must show current and prior year demand such as shipment, order , promotional data .

Example Data View

The data view must provide the level of detail needed to generate a fairly usable Adjusted History Base. Macro’s will help to identify outliers for user to understand how to address this aspect. Critical that user is able to view data by product grouping, brand, markets ect..The macro’s must also clearly provide exceptions allowing the user to prioritize their actions. Zero exception are also critical for user to analyses and understand.

Macro Cell Manipulation

This data view is one the most fundamental in that it provides the baseline data for statistical forecasting. Forecast formula’s , forecast accuracy formula’s all become irrelevant if the baseline is of little value.

STATISTICAL FORECAST MANAGEMENT

Forecasting is a mathematical activity which is part of the Demand Planning process.

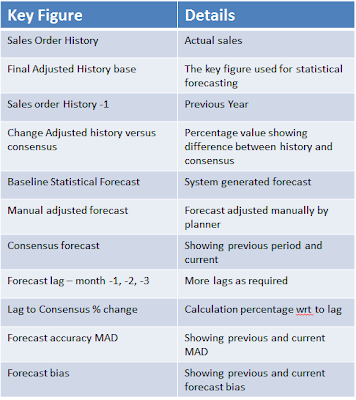

The data view used for forecasting must contain all the required data to effectively manage the forecast by the planner. It must provide required key figures that are needed for the planner to have clear view on how the forecast should be managed.

Sample data view

It must clearly show how forecast was determined and must provide all required data to manipulate and change forecast models and factors. It must also provide historical forecast accuracy performance data to indicate how well forecasting is progressing.

Std Forecast data

- It must have historical data for comparison purposes

- It must have forecast accuracy data to determine trends

- It must have alerts to efficiently manage exceptions with respect to forecast accuracy , outliers ect..

- It must allow focused data management; example flagging products that are phasing out and phasing in

- Monitoring and managing alpha, beta and gamma

Forecast Parameters

Alpha Factors

Beta Factors

Gamma Factors

The above is then critical for the user to review forecast results, carry-out the necessary changes such as changing the forecast model or factors.

Additional key figures that show bias values are also critical. These can help focused data with alert threshold for planner to rapidly review forecast data.

Forecast Accuracy Key Figure

CONSENSUS FORECASTING PROCESS

Once forecasting is completed, there is normally some form of consensus forecasting done with other entities like sales and marketing , production.

This is critical to ensure alignment with sales and marketing , alignment with production. It is no use having forecast that cannot be satisfied by production resources, or demand that is not aligned with promotions/campaigns.

Data aggregation is critical when reviewing data with the specific business entity like marketing. Furthermore not only is data aggregation critical but also time disaggregation.

Example Data View

Depending on target for consensus review, it could be that both monthly and quarterly data buckets will be required:

Monthly View

Quarterly View

This is critical for data view and having data granularity to suit the end target.

The data must be specific and uncluttered with unnecessary data.

Data View

As shown above, focused data for marketing review, data aggregation of data is critical; example customer group, brand ect…, and must clearly control how data at lower level is re-determined.

Dissagregation

LEAN VIEWS:

Depending on target (maybe production), helpful to have multiple data view including lean views. Lean views mean that only have basic data containing limited key figures at aggregated view. Example would be reviewing data with marketing team, different data elements when reviewing data with manufacturing.

The above defines the minimum data needed to review data with specific business entity.

ALERT MANAGEMENT

The Demand Planning process needs to be supported by robust alert and exception management to help relevant planner to address specific data results in order to be efficient considering the possible high data volume. It is critical that alert are process relevant to facilitate the applicable process.

Macro’s play a key role in managing alerts in the relevant data view. Sometimes alerts have to redetermine certain forecast error calculation. Typical consideration:

The mean absolute percentage error (MAPE), also known as mean absolute percentage deviation (MAPD), is a measure of accuracy of a method for constructing fitted time series values in statistics, specifically in trend estimation usually expresses accuracy as a percentage, and is defined by the formula:

Although the concept of MAPE sounds very simple and convincing, it has a major drawbacks in practical application ; If there are zero values (which sometimes happens for example in demand series) there will be a division by zero. This is an area where a custom macro could help to build own logic. Note; SAP provides standard macro function, but nothing stops one from creating totally new function (custom function module) with own logic.

Concluding remarks: The key around having Demand effectiveness that drives the Supply Chain is a well defined Demand Planning Process which results in meaningful product demand that not only will result in high level of forecast accuracy but must ensure required product availability across the supply chain demand elements. Forecasting is a sub-set of Demand Planning and has critical dependencies in order to generate meaningful forecast.