Traceability within a Complex Supply Chain flow and Distributed System Architecture (multiple EWM systems) and multiple software platform (SAP ERP, TM, legacy ect…).

OVERVIEW:

Organization’s require traceability either due to legal requirements or due to quality control requirements.

Traceability normally consists of defining detailed characteristics of a handling Unit and it its product, batch characteristics (expiry date, certificate ect..) and as well tracking across their micro (within plant) and macro (extra plant) supply chain.

Furthermore, in most cases traceability data must be kept for a number of years and must be available even though data has being archived. Further complexity is to be able to track within the pipeline based on specific characteristics such as batch number, mould number to determine its location and its association (production order, sales order )

Most organisations have complex supply chain flows, they can normally be within plant flow where batches / Handling units are received and processed across multiple steps. The characteristics of the batch and Handling unit may change as they are processed through various nodes of the supply network. Typical example would be temperature controlled items, expiry date ect…In this physical flow from a Micro physical flow.

Furthermore, a Handling Unit can also be processed externally across multiple Supply Chain Units, across many organisations units such as other distribution centres, customer etc..as show in the macro physical flow.

Macro Flow Physical Flow

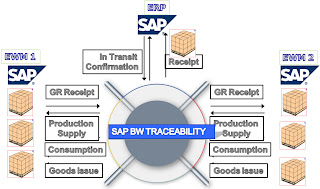

The above Supply Chain flows may also be supported by distributed IT network that are managed by individual SAP systems such as ECC , EWM and TM systems as well as legacy system. In each of these system there are processes that are specific to their relevant supply chain and have to be tracked. There are further situation where macro flows jump from one system to the other. Typical example is a Handling Unit produced and processed in one plant that is manage in System X, it then is sent to another plant via ship, the shipping is managed by system Y and eventually received in relevant plant system Y.

These multiple system creates a traceability dilemma in that having a single point view with respect to traceability becomes a serious problem.

Traceability update

This can be resolved with a centralized traceability system where its update is based on update rule from the various system. Update rule must contain the relevant event’s that should update the traceability system. This can be when a handling Unit is received from production, the traceability system will then be updated with the handling unit characteristics , its relevant status and its process status. An update rule could apply if handling blocked by quality department.

The ability of updating characteristics allows tracing of handling units based on characteristics of the Handling unit. The traceability not only will provide a full history of its process events and the latest status.

SOLUTION

Having provided a view on Supply Chain complexity with respect to Traceability and technology elements that are present in a complex supply chain, the solution would be a single point of data storage and extraction (reporting). This can be done by using SAP BW whereby traceability data is stored in relevant cubes and can be updated via updates rules from multiple systems.

The traceability system will be updated from the various system based on common updates rules defined for relevant process events that are critical for traceability.

The fundamental design requires two critical definitions:

- The characteristics of the Handling Unit. In the definition of the characteristics it is imperative to define the critical key data elements that need to be maintained in the traceability. The data elements will be critical for tracking and reporting. From a reporting perspective data elements such as batch number, usability of the batch, tool number, certificate ect..This will then allow searching for related HU, example; search for usage of HU that was manufactured by a specific tool, or search all semi finished product HU where in put product was part of a specific batch.

- The update rules that will update the characteristics; only key saupply process need to be controlled and updated in the traceability system. Typcial update rule if when HU is born, when received from production, when shipped out to another manufacturing plant.

The update of the centralized traceability system will then provide a central repository system that will contain complete flows thorough supply chain. This system will also provide status of each Handling unit and will allow the relevant user to take the required action should need arise due to specific requirement. Possible example relates to pharmaceutical environment where due a specific batch all Handling Units have to be traced through its pipeline. The traceability system will also provide a multi dimensional flow from raw materials, to semi-finished to completed manufactured item. This is critical should search for a specific batch of a raw material right through its usage up their final state (finished product).

The above shows how the traceability system is updated via the update rule as a Handling Unit is processed through the supply chain.

Although RFID system may provide this kind of traceability, it will still have a narrow views and will not have the flexibility of a custom traceability that one can define characteristic unique to one’s business.