This downturn implies over-supply of IT resources exceeding demand, rates have dropped to 50% of 2008, and some consulting companies are providing 2 for 1 especially the (small consulting companies). Even at these reduced rates IT investment is not taking off. The reasons for this are as follows:

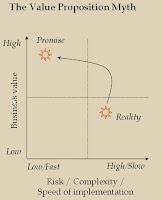

1: Business is weary of IT, they see IT as cost builder rather than cost reducer, these continuous new acronyms (SOA/BPMN) do not really bring business benefits if they are not orientated towards business needs. See below the ‘Value Proposition Myth’

2: The over-supply of low cost consultants has resulted in many disasters, limited business benefits Having stated the above, are there opportunities for IT investment during this serious downturn?

In my opinion, YES.

These opportunities could be:

● IT RATIONILIZATION

● NICHE IMPLEMENTATION

● BUSINESS OPTIMIZATION

IT RATIONILIZATION

Rationalization of IT infrastructure;

How many multi-national companies out there have a disaster in place, many ERP systems (different types, SAP, ORACLE, JDE, different versions/release ect…) with costly interfaces and costly IT resources supporting these systems. I have even seen a SAP System Sales Order mgt, integrated with Oracle Delivery processing , integrated with a Catalyst Warehouse Management system integrated with a Transportation system (four system to manage Order to Cash) with complex custom interfaces, many support teams and many consulting companies.

Why is this? Very simple IT Managers approach in the past was the more complex, the bigger the budget, the bigger the power (parking space next to VP and personal secretary and nice office).

I recently worked on a APO Planning Project (DP and SNP) in a consumer environment whereby every time there was a roll-out to a new country a totally new project was started instead of making use of existing core template (actually most IT manager have no clue of what a template is) resulting in costly implementation and costly support (people and infrastructure). Even worse, the project was based on replicating a legacy logic built in EXCEL instead of really adopting a SCM optimization project.

Rationalization means getting rid of all the fluff and consolidating into one ERP/Planning System , single server architecture across all continents/countries. Cost saving is enormous. This actually contradicts SOA and adoption of the so called ‘Cloud Computing’

To make this a success the following are critical aspects to consider:

● Project ownership must be with business not IT (possibly a Finance VP)

● Strong project governance is needed (tools, control framework, methodology) with respect to managing the global rationalization. The rules of game must be clear.

● Manage project internally, use consulting companies or contract consultants to provide specialized resources on demand, using a consulting company to manage a IT rationalization normally has limited success, consulting companies objective is to bill as much as possible therefore strong conflict

● A system baseline is needed (template) of the ERP and SCM System, this baseline becomes the core for any global roll-out, rules for changes must be simple:

► Legal requirements (Country X requires that any delivery that cross regional borders requires certain financial requirements)

► Customer Service related, will the functionality result in poor customer service (obviously consideration of business volume is critical)

► Cost and Efficiency related, will it result in more people to pick pallets in my warehouse. Cost efficiency consideration must also look at cost of IT, no use in implementing a best of breed because you plan to save 2 forklift drivers but at the same time need to employ costly IT support people and costly interfaces

● Have a strong Design and Implementation Architects (people that know business and IT) that are able to link business needs with a solid IT solution. This means people that come from solid business background and have solid IT experience. People that can provide guidance to IT manager have to make smart decisions..

● To make the various VP interested (the ones that approve the project) IT managers will have limited success in trying to sell this, why? Simple, admission of their own failure. Best to use consulting companies (not IT) better Strategic or Auditing firms to approach the relevant VP. This is also an opportunity for SAP do some good solid marketing, it also in their interest to get rid of all the ‘Fluff’.

NICHE TOOLS IMPLEMENTATION

SAP has released over past couple of years within the Supply Chain Framework many new functionalities that could provide a business benefit. Typically to name a couple these functionalities:

► SCM Event Management

► SCM EWM (Extended Warehouse Management)

► SCM SPP (Service Parts Planning)

The problem with this is that IT must be able to sell this kind of project, success can be achieved if these functionalities can provide a perceived benefit in terms of IT rationalization or Business Optimization. A further problem is that most consulting companies have limited skills to implement these niche functionalities, you will not find the usual ‘low cost resource’ consultant.

The problem with this is that IT must be able to sell this kind of project, success can be achieved if these functionalities can provide a perceived benefit in terms of IT rationalization or Business Optimization. A further problem is that most consulting companies have limited skills to implement these niche functionalities, you will not find the usual ‘low cost resource’ consultant.BUSINESS OPTIMIZATION

This is more difficult to manage mainly due to lack of management skills, optimization from a IT perspective tends to fail because of trying to look at things from IT perspective only and not from a business perspective. Real optimization requires a good understating of Business and Mechanism needed to support a process (IT, manufacturing infrastructure ect..).

Optimization is like trying to fine-tune a symphony orchestra. Imagine trying to tune a violin without considering other instruments, or imagine sheet music for 1st violinist that in not in tune with a Cello.

Optimization in Supply Chain means doing things more efficiently (cost effectiveness).

● Right qty at the right place at the right time at lowest possible cost. (Planning, distribution and transportation)

● Supply Chain Network, most cost efficient network to deliver product to market. (centralized warehousing, multi-market warehouse), transportation methods, loading , route mgt.

● Producing more of the right product based on customer demand without increasing inventories (on time delivery, maximum manufacturing output at lowest inventory levels)

● Obsolescence avoidance.

● Inventory optimization; What is the optimal inventory policy that minimizes inventory holding cost while maintaining or improving serviceability and financial performance.

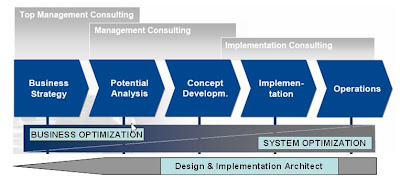

The fundamental aspect when undertaking a optimization project is to consider the above framework in order to ensure maximum success. Trying to focus only in System Optimization results in limited benefit. The ideal is to determine the correct synergy between Business Optimization and System Optimization so that the end result is a IT solution that totally supports business needs and achieves optimization objectives.

Some typical examples regarding the optimization framework;

Consider a SCM project whereby one of the possible optimization objectives is the rationalization of distribution center’s. This kind of work requires the following:

Business Optimization

This covers business strategy, understanding potential solutions and defining a TO-BE model.

The impact to the business with respect to distribution rationalization. This also includes opportunity assessment.

Business potential analysis from a cost effectiveness situation and other consideration such as tax implications, local Government benefits ect…

A conceptual TO-BE (Business Process Re-design, benchmarking) design Blueprint, organizational change, is needed to address location, type of warehouse, business model that leads to the desired cost effectives.

Implementation Consulting

This entails implementing and providing operational support for the conceptual TO-BE model with the ideal IT infrastructure.

Design , Build and implementation of the required IT tools, this could be the usage of existing functionality provided by the current ERP or SCM platform with the ideal hardware platform.

Operational IT system support.

I recently worked on a optimization project related production planning and execution, this was in the auto component supply. Reality was that business had very low confidence in the SAP IT solution, customer service was bad (50% on time delivery) inventories too high; too much was manufactured of the wrong product. Through the years, IT invested a lot of money bringing in consulting companies to try and fix the problem, but never succeeded because they always tried to optimize the IT part and never really understanding what was happening from a business perspective. Obviously IT and SAP was not well considered in the organization. This changed when the VP decided to personally engage the problem by using a consulting company specialized in manufacturing (not SAP or any IT system) to do a detailed work-study analysis and understand what exactly was happening within manufacturing, planning and execution and to identify a TO-BE situation, then based on the TO-BE model was the SAP System Optimized resulting in improved performance.

The above shows that there are different roles and skill set’s needed, the difficulty is to manage these task and clearly understand what skill sets are needed keeping in mind that during optimization process there are many role-players to consider. Not many organization have Change/Optimization champions that can mange an optimization project. Most IT managers lack ability to understand the grey area related to Business Optimization versus System Optimization.

The role of a skilled Design and Implementation Architect is also critical, this person normally not only has strong business skill but also has strong system expertise and help’s to bridge gap between Business Optimization and System Optimization and also provie guidance to what is technically possible.